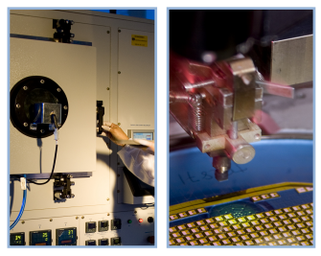

Wafer Saw

- 3 mils to 34 mils thick

- 8 inches wafer diameter

- Si, GaN-on-Si, and SiC

- Auto wafer saw and Ultratech Cleaner with CO2 Re-ionizer to maintain water resistivity of 0.1 to 1 Mohm-cm

- 100% saw through and partial cut

Die and DBC Attach

- Soft and Eutectic solder attach process using belt furnace, vacuum oven and auto die attach (with leaded and leadfree capability)

- Automated Solder Paste application

Wirebond

- Ultrasonic bonding

- Automatic wirebonder; capable for Aluminum wires (1.25 to 20 mils aluminum wire 99.99% or 99.999%)

- Fully automatic equipment, deep access with stitch-bonding

capability.

MOLD (for Discrete Packages)

- Conventional mold die sets with auto-frame loaders (120 to 175 tons capacity)

- Sensor equipped pellet pre-heaters

- Green mold compound technology

Marking (Discrete Packages)

- Laser engraved marking

Marking (For Module Packages)

- Marking using sticker label

- Computer-based Zebra thermal printer

Trim and Form (For Discrete Packages)

- Dedicated DTFS die sets for plastic packages.

- Hydraulic press (max capacity 1500psi)

- Pneumatic press (max capacity 100psi)